Introduction: The jewelry industry is one of the earliest industries to adopt 3D printing prototypes and indirect production (through casting models). Therefore, there are some software and software plugins specifically designed to meet the needs of jewelry merchants. Rhino, developed by Rhinoceros, has been a leading choice almost from the beginning. Now, with Grasshopper and several additional components specifically designed for jewelry development, it has indeed dominated the market for professional jewelry design software. From the smallest boutique to some of the world's largest manufacturers, many different operators in the entire jewelry industry are using it. Rhino serves as the host platform for multiple industry-leading jewelry design plugins, such as CrossGems, Stuller's MatrixGold, and CounterSketch, making designs faster and more efficient.

![]()

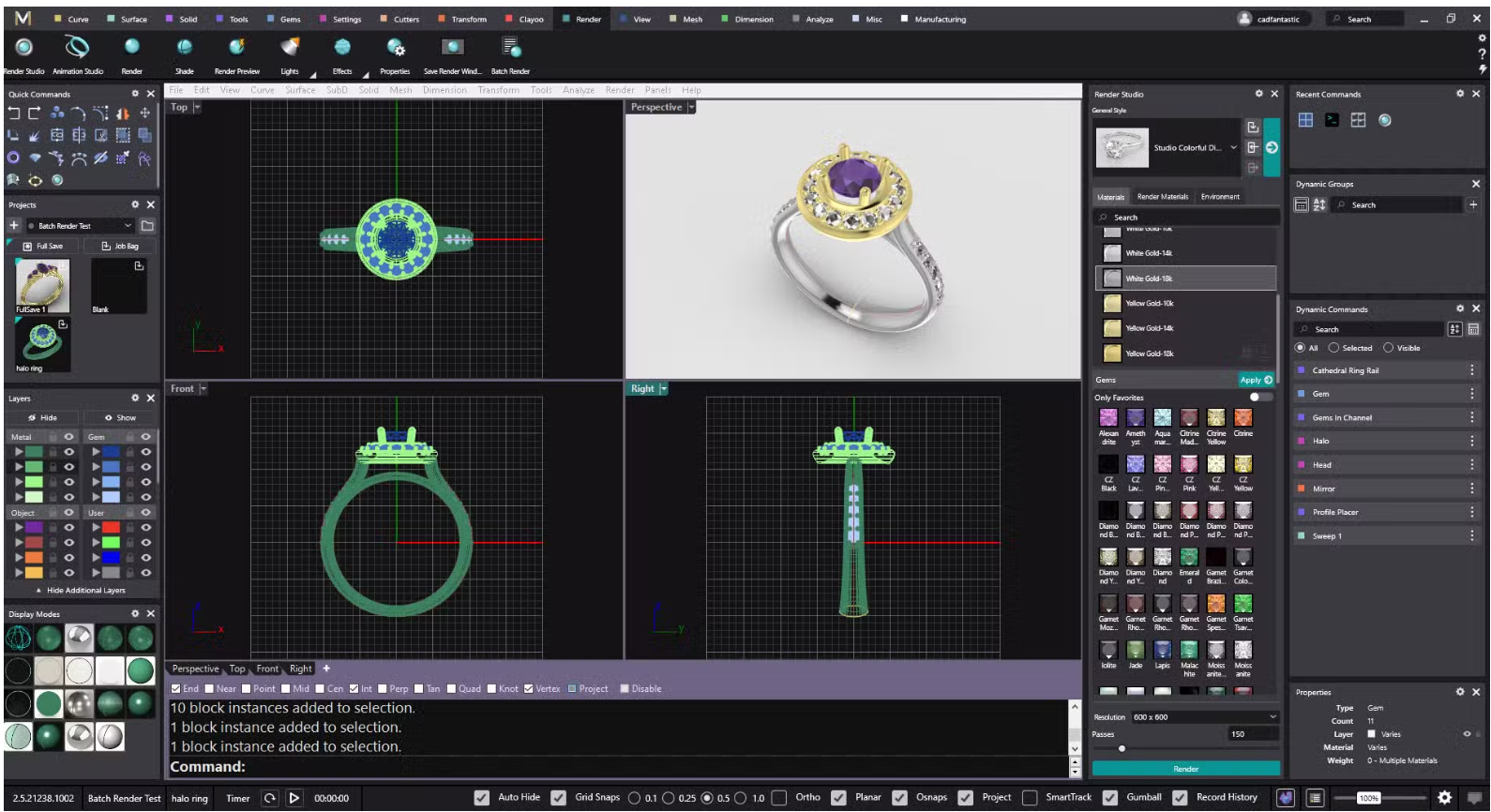

Rhino 8 has become an ideal tool for exploring and developing diverse jewelry designs through 3D printing. Its universal modeling tool provides a highly flexible way to convert designs into 3D. Users benefit from

accurate NURBS geometric modeling, real-time visualization of changes, and the ability to measure quality attributes. The platform also provides a wide range of training materials, videos, and support, suitable for

users of all skill levels. Rhino 8 Evaluation Edition is suitable for Windows and Mac, allowing designers to experience its features firsthand.

One of Rhino's main functions is its ability to visualize designs before casting. This feature allows jewelers to create renderings of their works that can be sold without the cost of building each piece. Rhino supports

many popular rendering plugins, providing advanced real-time rendering, multiple illustration display modes, and the ability to convert images into 2D illustration graphics. It seamlessly integrates with popular graphics

products such as V-Ray and KeyShot, enhancing the visualization process.

Digital manufacturing integration

Rhino seamlessly integrates into every step of jewelry manufacturing and 3D printing processes. Whether ordering raw castings or utilizing digital manufacturing methods and 3D printing, Rhino ensures accurate,

symmetrical, and detailed casting models. It supports outputting precise geometric shapes for manufacturing, exporting 2D drawings and rendering, and creating 3D STL files for 3D printing on industry-leading printers

such as ETEC, Asiga, 3D Systems, DWS, and SolidScape.

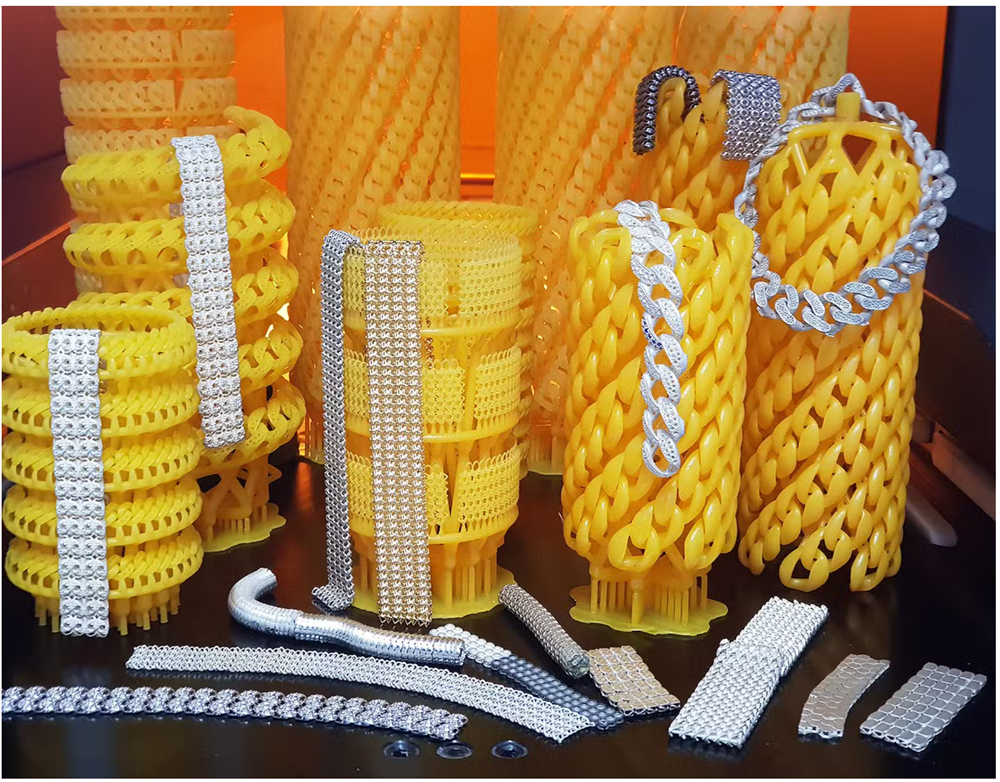

Casting model from 3D printer.

Nowadays, Rhino has become the preferred choice for many of the largest suppliers and manufacturers in the jewelry industry, including end-to-end 3D printing service providers. Its brand specific plugins can link 3D

models to real-time inventory, such as gemstones, inlays, and discoveries. Professional level plugins such as CrossGems, MatrixGold, Pro-J, and RhinoArtisan provide professional 3D jewelry design features, combining

advanced features with user-friendly interfaces to make the design process more efficient and effective.

Rhino integrates with its algorithm design tool Grasshopper to explore and develop various solutions. Grasshopper facilitates the creation of parameterized systems, exploration of organic repetitions, integration of

intelligent datasets, as well as formal optimization and the use of organizational topology and analysis. Various resources such as the Generative Jewelry Community and Peacock for Grasshopper support jewelers in

utilizing these advanced tools.

Screenshot of Rhino's jewelry plugin MatrixGold

It should also be said that Rhino is useful for creating individual jewelry 3D models, but when producing them on a large scale through wax loss casting, other techniques are needed to produce a large number of

"casting trees". One of them is DWS's NautaXCluster technology, which is a software technology that combines high-resolution 3D printing with wax loss casting in a fully digital workflow. It is used in combination

with DWS advanced casting materials and 3D lithography printers to fully digitize and automate production.

In XCluster, the concept of casting trees has completely changed, replacing the central core of all branches with a new geometric structure called a cluster. Without a central core, higher density and efficiency can be

achieved, allowing for more objects to be accommodated in the same flask and requiring much less metal. A single cylinder can accommodate up to 2000 objects of any complexity.

The latest Nauta XCluster chain version from DWS can directly produce cast trees for chain manufacturing

DWS has recently launched the NautaXCluster Chain version, which completes the workflow through direct linking between 3D printing and casting, specifically for chain manufacturing. Its purpose is to exponentially

increase creativity by implementing connected, solderless chains that cannot be produced by any other method, then expand the market, and provide better quality products without all the typical interventions of

traditional production.

The Nauta XCluster Chain software can automatically prepare files by first adjusting the diameter of the cluster to fit the flask, and then managing the required length of the bracelet/necklace and all necessary casting

gates by using a spiral structure. Different types of designs can be generated within the same cluster for maximum flexibility. Finally, the software places the drum in the working area of the available printer to prepare for

the printing phase

Screenshot of 3Design

Jewelry 3D printing and other applications

Rhino's reputation in the jewelry design industry is matched by its extensive training channels. The Gem Institute (GIA), Fashion Technology Institute (FIT), Goldsmiths Center, and Texas Jewelry Technology Institute provide

world-class education and training. In addition, online platforms such as Rhino Jewelry CAD, CAD Jewelry School, and PJ Chen Design provide easy-to-use training resources to ensure that jewelers can fully utilize Rhino's

capabilities.

Rhino integrates with its algorithm design tool Grasshopper to explore and develop various solutions. Grasshopper facilitates the creation of parameterized systems, exploration of organic repetitions, integration of

intelligent datasets, as well as formal optimization and the use of organizational topology and analysis. Various resources such as the Generative Jewelry Community and Peacock for Grasshopper support jewelers in

utilizing these advanced tools.

There are many other jewelry design programs, but most of them have been replaced (or integrated into) by Rhino and its various additional components. Among them, 3Design is a CAD software completely dedicated

to jewelry design, manufactured by jewelers and serving them. Through this program, users can create highly detailed 3D objects and visualize realistic images of 3D models before printing. Another interesting application

for customizing jewelry is Jweel, a parameterized online application (created in the early 2010s but still running today) that does not require any 3D modeling knowledge. It has a very simple navigation screen that allows

users to quickly design personalized jewelry, such as jewelry with text or symbols. After creating a customized part, it can be exported as an OBJ file for 3D printing.