In May 2024, NASA allocated $300000 to Florida State University (FSU) and Florida Agricultural and Mechanical University (FAMU) to support a project using 3D printing technology to develop cutting-edge sensors capable of withstanding harsh and extreme conditions in space. These devices are crucial for space missions and can significantly improve the durability and accuracy of spacecraft monitoring systems. The project is titled "Electronic Additive Manufacturing for NASA Applications" and is a collaboration between FSU and FAMU's Joint Venture Engineering School.

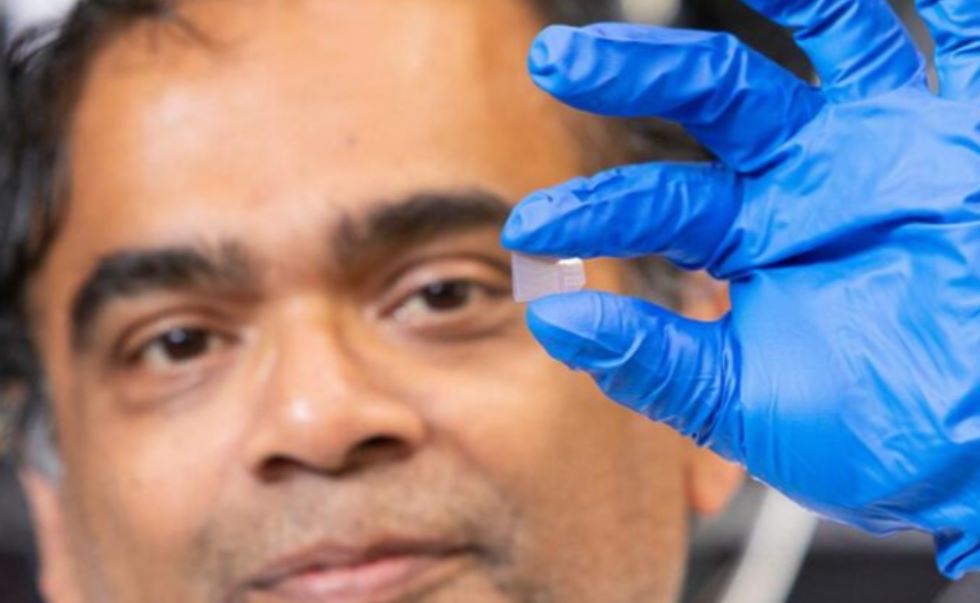

A multidisciplinary research team led by chemistry and biomedical engineering professor Subramanian Ramakrishnan has produced strain

sensors based on silver ink for various NASA space projects, which can accurately transmit changes in real-time using conductive silver ink to

help predict and prevent potential failures. These sensors are crucial for monitoring the structural integrity of spacecraft, measuring how

materials stretch and compress under pressure to ensure the safety and functionality of critical components of the spacecraft during missions.

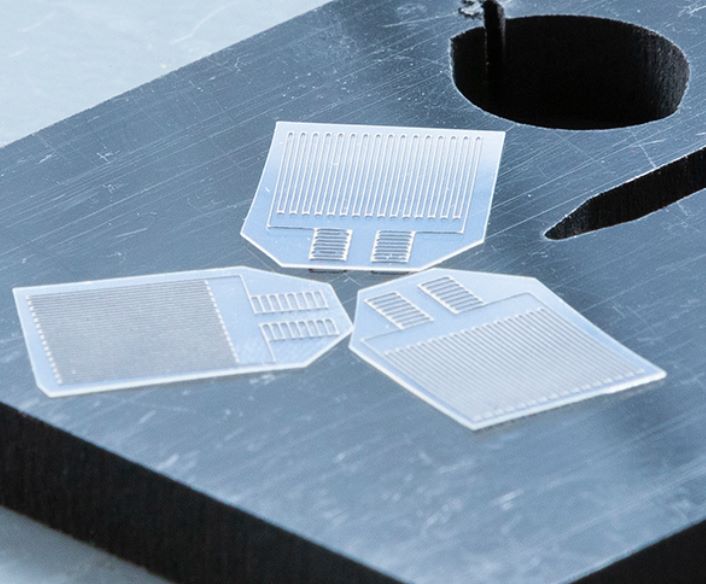

The team used 3D printing technology combined with laser annealing method to design sensors superior to traditional strain sensors. Laser

annealing involves using a focused laser beam to heat and print silver ink, improving its electrical and mechanical properties without melting.

Researchers say that this technology enhances sensor performance, resulting in devices with high strain coefficients (measuring the sensitivity

of sensors to strain). The increase in sensitivity enables sensors to more accurately detect changes under pressure or strain.

Strain sensors at the High Performance Materials Research Institute of the Materials Research Building at FAMU-FSU Engineering College in Tallahassee, Florida

Ramakrishnan pointed out that these sensors were created using newly purchased nScropt machines and can be printed on curved surfaces,

which is a key feature of aerospace applications. The nScript machine used in the project is renowned for its precision and versatility, relying on

SmartPump micro dot adhesive tool heads to print directly on curved and irregular surfaces. This feature was launched in 2021 and is very

suitable for installing sensors on non planar components of spacecraft.

In addition to aerospace, nScropt's technology also has the potential to change various industries by encouraging the direct production of

complex electronic products on object surfaces. This can bring innovation in wearable technology for embedded sensors, medical devices

suitable for personal anatomical structures, and even drones and satellite components. The rapid operation and compatibility with multiple

materials of nScript make it a powerful tool for accelerating product development and reducing manufacturing costs.

Although laser annealing is not new, combining it with 3D printed electronic devices for space projects is an innovative step in sensor design.

This cross disciplinary research aims to produce more sensitive and durable sensors, making them more suitable for harsh space conditions.

Precision micro glue, material extrusion, micro milling, and picking and placing tool heads can run on the nScropt Factory in the tool

As part of the NASA Science Mission Board (SMD) Bridge Program, this project aims to promote diversity, fairness, inclusiveness, and

accessibility among NASA's workforce and the broader American scientific and engineering community. This is part of NASA's first funding

to support emerging research institutions.

Shahra Lambert, senior engagement consultant at NASA, said, "As the agency continues to establish relationships with resource constrained

institutions through initiatives such as the 'Bridge Program', it intends to provide fair access to NASA for the best talents in the United States.

These partnerships will help NASA cultivate a diverse and capable workforce to drive human exploration of the universe."

NScropt technology

NScropt technology is an advanced 3D printing and micro distribution manufacturing solution known for its high precision and wide material

selection. Key features of this technology include:

● Precision micro distribution: nScript's equipment can accurately distribute various materials, including biological materials, conductive

materials, and structural materials.

Direct Digital Manufacturing (DDM): This technology supports the direct manufacturing of complex multi material products from digital files,

not just parts.

● Electronics and Packaging: nScropt technology can be used to print circuit structures and electronic devices, providing a new method of

electronic manufacturing.

SmartPump ™ And nFD ™ Tool heads: These tool heads support printing using plastic, metal, ceramic, and composite materials, and can

combine multiple materials in a single construction, with excellent tolerance control and accuracy.

NScropt's technology is suitable for applications that require high precision and repeatability, such as biological manufacturing, 3D printed

electronics, and precision micro distribution. In addition, nScript's printing system also features replaceable print heads, which can achieve a

smooth surface with subtle features without the need for post-processing.