Marine energy converts the kinetic energy of natural phenomena such as water currents and tides into clean energy, providing electricity to local coastal communities, and has broad prospects in the renewable energy industry. According to data from the Office of Energy Efficiency and Renewable Energy in the United States, ocean energy resources will account for 57% of the country's total electricity generation in 2019. The potential for ocean energy is enormous, and the United States is undertaking many innovative projects aimed at promoting the development of this renewable resource.

In May 2024, researchers from the National Renewable Energy Laboratory (NREL) in the United States collaborated with the Pacific Northwest National Laboratory to study how

additive manufacturing can enhance ocean energy technology, with a particular focus on tidal power generation, which uses turbine technology to convert energy from tidal water into

usable electricity.

Over the past two years, the project has been testing and analyzing various materials and printing technologies in the development and production of tidal turbine wing beams. The

turbine wing beam is the load-bearing component inside the turbine assembly, used to fix the turbine blades in place. This component must not only be able to support the turbine

structure, but also withstand corrosion in the marine environment. After evaluation, researchers found that thermoplastic 3D printing is not suitable for this specific application, and the

best choices for producing tidal turbine wing beams are stainless steel materials and laser metal deposition technology.

From left: NREL researchers Miguel Gonz á lez Montejo and Paul Murdy

"Additive manufacturing has the potential to produce very sturdy and hard structures, which will benefit marine energy," said Paul Murdy, NREL mechanical engineer and chief

researcher in additive manufacturing for marine energy

The NREL team is developing 3D printed turbine wing beams suitable for existing tidal turbine systems, which can facilitate rapid prototyping of new marine energy equipment in

various blue economic sectors such as aquaculture and microgrids, thereby providing electricity to coastal communities. In the future, this will also make it easier for coastal towns and

communities to replace worn-out components in marine energy systems through local printing, thereby reducing dependence on the supply chain.

NREL researcher Miguel Gonz á lez Montejo, who designed the component, said, "For specific communities in specific regions, ocean energy may change the rules of the game. For

example, my hometown Puerto Rico can benefit from an upgraded energy grid that integrates renewable energy technologies such as ocean fluid power. These technologies can help

many small towns establish energy resilience and independence while providing renewable electricity from local sources."

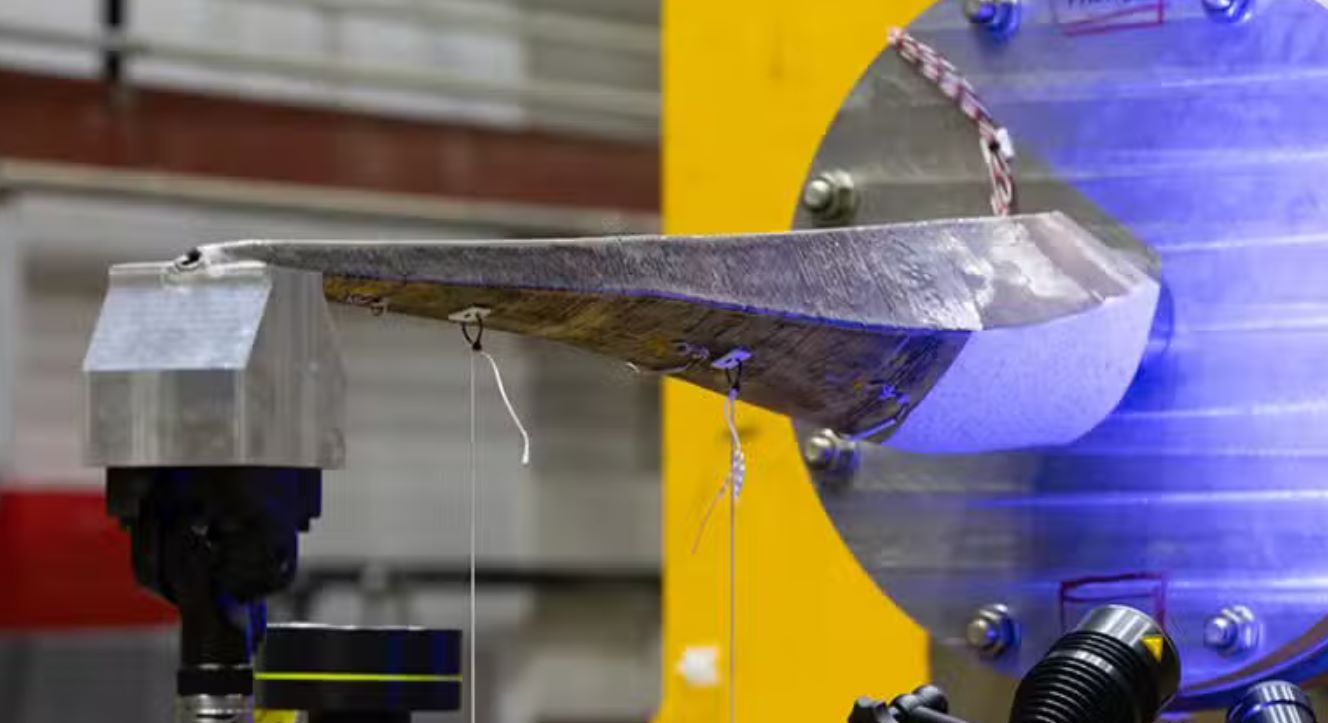

The tidal turbine wing beam is being tested using hydraulic actuators

At present, 3D printed tidal turbine wing beams are undergoing fatigue testing and 1900 pound load testing at NREL facilities (50% higher than the expected load in marine

environments). The turbine wing beam of this iteration is 3D printed using AI Build's robot system and stainless steel materials, and the printing process takes about a week. Miguel

Gonz á lez Montejo said, "Structural validation ensures that wing beams can respond to real-life forces in the manner predicted by the model, allowing us to understand the differences

between new additive manufacturing processes and traditional steel manufacturing technologies."

This test marks the final stage of research work. After the testing is completed, NREL researchers will continue to develop and fine tune the design of 3D printed turbine wing beams,

and explore other potential applications of additive manufacturing in marine energy.